MicroSim Overview

1. Introduction

MicroSim short for Microstructural Simulator is a software stack consisting of phase-field codes based on differing discretization strategies (finite difference, finite volume and Fast Fourier transform) along with implementation on varied high-performance computing infrastructure such as MPI(CPU), CUDA(GPU) and OpenCl(GPU). The motivation for the creation of this software stack is to provide the academic and industrial user base a open-source software framework that can be utilized readily or with minimal modifications for routine problems relating to phase transformations during materials processing. The present release is the first among many of our software stack that will be presently be able to address phase transformations such as solidification and precipitation.

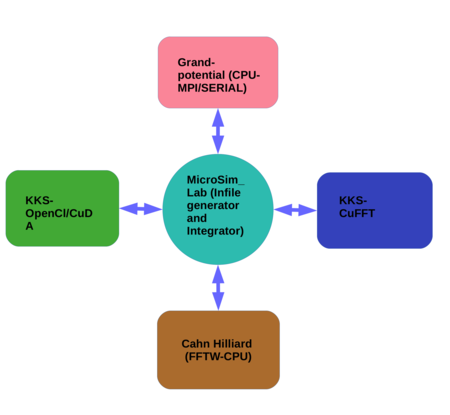

2. Generic structure of the stack

The software stack is described in Figure below. A brief description of the modules follows:

Grand-potential based solver:

This is a multi-phase multicomponent phase-field solver based on a regular-grid finite-difference discretization, with a simple Euler forward time marching scheme. It is based on the phase-field model presented in Phys. Rev. E 85, 021602 (2012). Two versions of the solver are available, one which is a serial code that runs on the CPU and the second that is parallelized using a simple block domain- decomposition using MPI. Presently, these solvers are discretized in 2D and future releases will contain more features as well as domain discretization in 3D. A dedicated module related to its usage can be found in the solver folders.

Kim Kim Suzuki(KKS) based model (OpenCl):

This is a multi-component based solver that is based on the Kim Kim Suzuki model which uses a finite difference discretization with explicit time stepping. The code utilizes the OpenCl based framework for utilizing both CPU and GPU infrastructure. The solver allows for parsing in a .tdb file for reading in the thermodynamic information directly into the phase-field formulation. Presently the code has been implemented for 2D and future releases will contain more features as well as the more generic 3D solver. A dedicated module related to its usage can be found in the solver folders.

Kim Kim Suzuki(KKS) based model (CUDA):

This is a binary alloy solver that is based on the Kim Kim Suzuki model and utilizes the Fourier transform for the solution of PDEs by leveraging the CuFFT libraries as part of CUDA. The solver is meant for utilizing the NVIDIA GPU graphic cards particularly the Tesla-P100 and later cards. Because of the Fourier transform discretization this solver module has by default periodic boundary conditions. The code can be utilized for both 2D and 3D geometries and is presently written for utilizing single GPU cards. Later versions of the code will be extended for the treatment of multiple phases and components as well as parallelization on multiple GPUs. A dedicated module related to its usage can be found in the solver folders.

Cahn-Hilliard model (FFTW):

This is a binary alloy solver that is based on the Cahn-Hilliard formulation and utilizes the Fourier transform based solution of PDEs by leveraging the FFTW3 libraries. The solver runs on single CPUs and it is meant for quick solutions to problems in smaller domains. Because of the Fourier transform discretization this solver module has by default periodic boundary conditions. The present solver is programmed for 2D domains that will be generalized for 3D do- mains in future releases. Along with this, the solver will also be extended for simulating multicomponent and multi-phase systems. A dedicated module related to its usage can be found in the solver folders.

MicroSim GUI:

MicroSim GUI is a Python interface that allows the user to create the input files and choose the solver of his choice for the execution. It integrates the preceding modules that are a result of in-house phase-field code development. The interface also allows for a direct call to the visualization software Paraview enabling the user to view the results of the simulation. MicroSim GUI comes with Post-processing tools such as dendrite tip radius, front velocity, front undercooling, precipitate size, precipitate count, volume fraction, surface area, triple point calculator etc.

OpenFoam based solvers:

Along with the preceding softwares that are a result of home-grown codes that have been integrated over the years, the software stack will also contain the Finite Volume based modules that are utilize the OpenFoam multiphysics platform. These will utilize the already developed interfaces as part of OpenFoam and the modules that will be shared as part of this software stack will contain an independent documentation of the module and its usage. Presently, a single-phase binary alloy solidification module that is based on the Grand-potential based formulation and utilizes adaptive mesh refinement will be part of this release. Future release will contain modules for two-phase eutectic growth. Since the modules utilize the OpenFoam framework, they are generic solvers for both 2D and 3D domains.

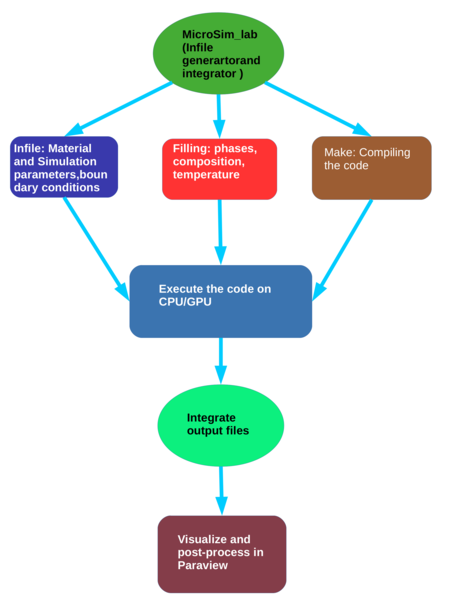

3. Process flow

In the following we describe briefly the workflow for getting the user ready with

his/her simulation, which is schematically described in Figure.

The MicroSimGUI interface allows one to gain experience in using the software by enabling navigation through the parameter set required for the solvers for their execution. The interface can be utilized for the generation of the “Infile” that details the important parameters that are needed for a particular solver along with the boundary conditions as well as the information of the initialization of the domain. The experienced user will be able to modify the Input and Filling files manually while the early users are encouraged to utilize the interface to gain familiarity with the different solvers and their input parameters. The interface can also be utilized as quick check for the parameters in the Input files as it enables one to run and visualize the simulation results in a single workflow. For the experienced user who makes a change to the original codes can also make use of the interface for compiling his codes readily.

4. Visualization and File types

Paraview is the default visualization software for the simulation results as well as associated post-processing. All the output files are written in a ”DATA” folder in the execution directory. The files are written in .vtk format, ASCII/BINARY depending on the user specification in the Infile for the serial or single GPU codes. For the MPI-based solvers (Grand-potential based solver(MPI)) the file formats are .vtk(ASCII) or .h5. For the MPI based solvers the .h5 files are reconstructed into .xml format for viewing in paraview, while a built-in exe- cutable ./reconstruct is utilized for reconstruction of .vtk(ASCII) files. Detailed description of the execution commands may be found in the individual manuals present in the solver folders.

MicroSim

MicroSim